About PTG

Performance Technologies Group, Inc. is a Manufacturers’ Representative company serving the northeastern US for over 25 years with an emphasis on the Electronics and Industrial Assembly markets. No matter your company’s production tools and equipment needs, PTG is committed to providing the best products and technical assistance you demand.

As a technical support conduit for the manufacturers we partner with, we pride ourselves in going above and beyond for our customers. We will work with you from assembly through inspection and rework, providing all the tools you need to get the job done.

Many products we represent are available for demonstration at your facility, providing assurance that the product is compatible with your process.

INDUSTRIES

- Aerospace

- Alternative Energy

- Automotive

- Consumer Electronics

- Contract Manufacturing

- Defense/Military

- Medical

- Industrial Electronics

- Life Sciences

- Lighting

- Security

- Telecommunications

- Wire/Cable

About PTG

As a technical support conduit for the manufacturers we partner with, we pride ourselves in going above and beyond for our customers. We will work with you from assembly through inspection and rework, providing all the tools you need to get the job done.

Many products we represent are available for demonstration at your facility, providing assurance that the product is compatible with your process. Our Demonstration Center located in Tyngsboro, MA, pictured above, is a convenient place to evaluate our tools on your product. ESD safe workstations are available for demonstrations on your ‘live’ assemblies. We are always more than happy to set up demonstrations, so your satisfaction is fully guaranteed.

INDUSTRIES

- Aerospace

- Alternative Energy

- Automotive

- Consumer Electronics

- Contract Manufacturing

- Defense/Military

- Medical

- Industrial Electronics

- Life Sciences

- Lighting

- Security

- Telecommunications

- Wire/Cable

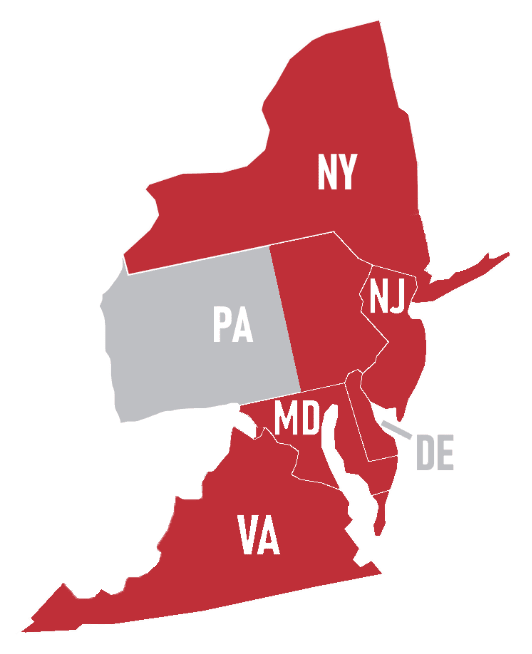

OUR TEAM

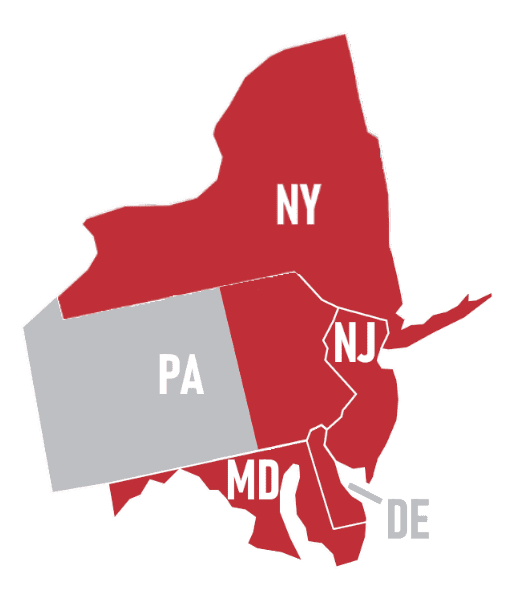

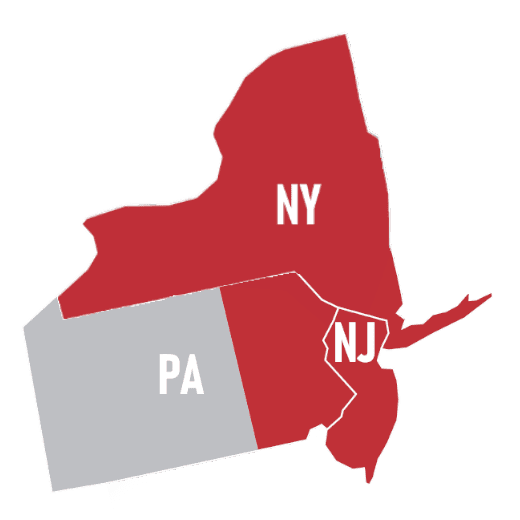

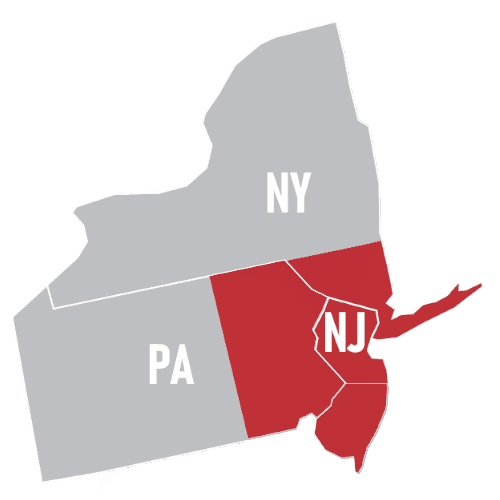

Zach Savana

Metro & Long Island NY , New Jersey

610.291.3550

(PDF) Download Line Card >

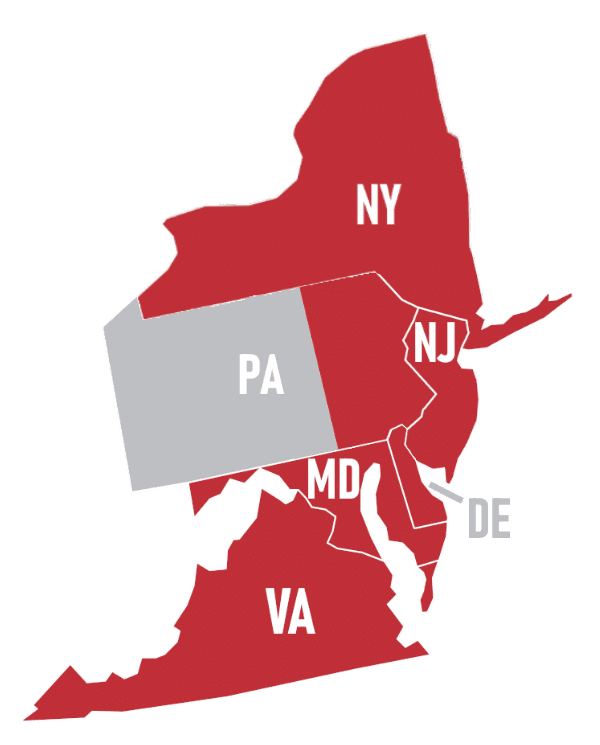

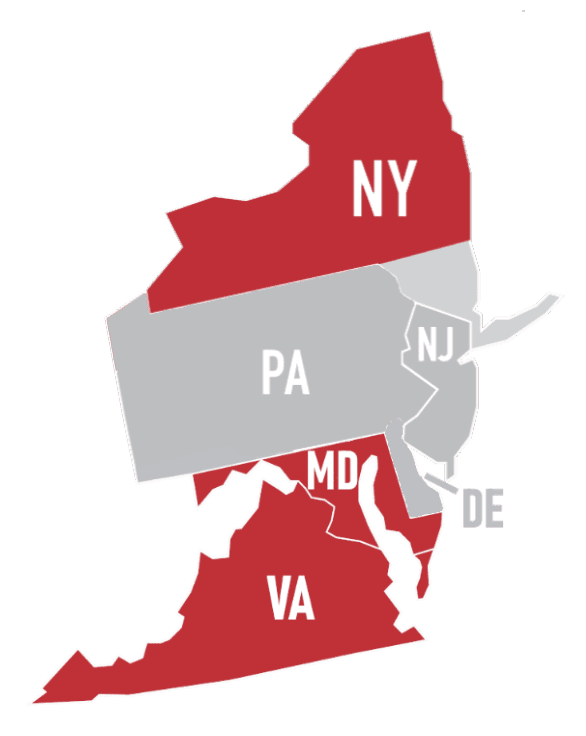

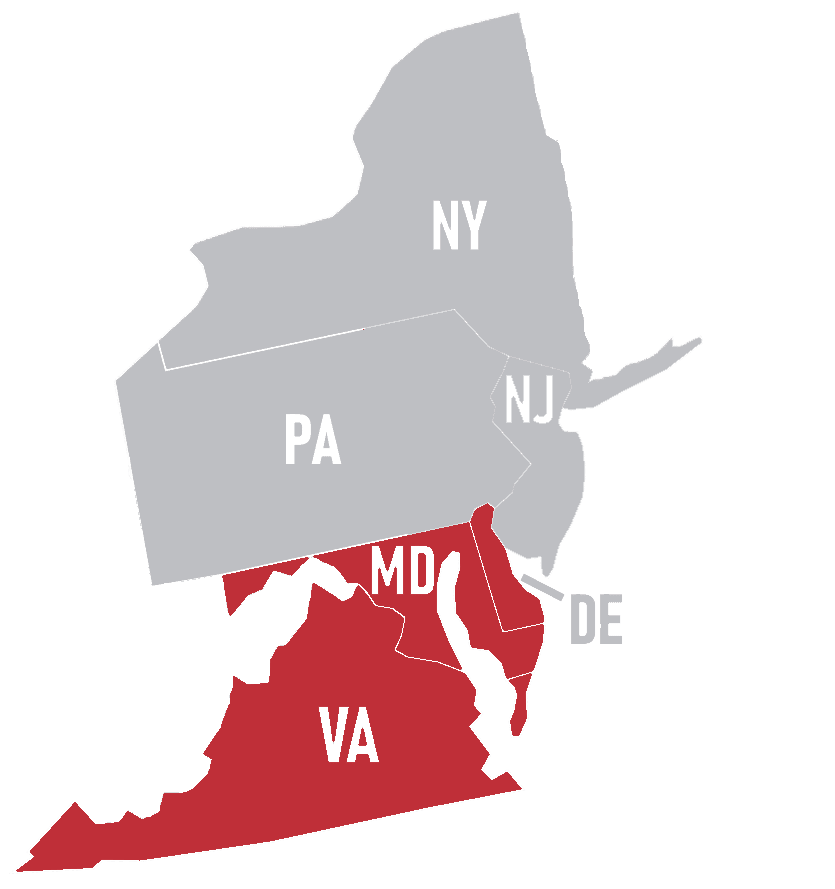

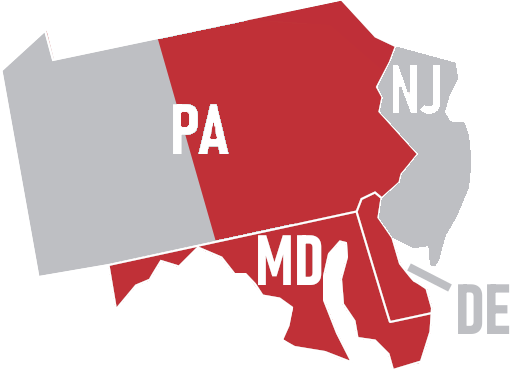

Conor Kilcullen

Maryland, Delaware & Pennsylvania

610.773.5807

(PDF) Download Line Card >

Zach Savana

Conor Kilcullen

Maryland, Delaware & Eastern Pennsylvania

Certified Facility ESD Auditor

610.773.5807

[email protected]

PROUDLY SHOWCASING OUR MANUFACTURERS

How Can We Help?

Use the form below to contact us with any questions.

We’ll get back to you shortly!